Next Gen Eco Materials 1 - Potato Peeling Chipboard

DIsturbed by the environmental impact and short lifespan of many readily disposable materials, Kingston University graduates Rowan Minkley and Robert Nicoll have employed waste potato peelings to create an eco-friendly and cradle to cradle alternative to damaging single-use materials like MDF and chipboard, giving it the pithy moniker 'Chip[s] Board®'.

"Finding a better use for potato waste is the holy grail for the potato processing industry."

— Nick Vermont, Retired Regional CEO, McCain Foods (GB) Ltd

The ubiquitous MDF is a very useful, cheap material, but it comes with a different price. It is damaging to the environment, requires toxic chemicals to produce and unable to be recycled. The UK furniture sector currently disposes of/incinerates 140,000 tonnes of MDF per year.

Minkley and Nicoll wanted to develop a material that, if it had to be thrown away, wouldn't have the same negative environmental impact and could even be easily repurposed with little effort. The board is fully biodegradable, able to be returned to the biological cycle by becoming fertiliser for plants or even animal feed. The new board unlike MDF, doesn't contain formaldehyde or other toxic chemicals.

The duo believe that the circular economy should be the starting point when designing any new products and materials. And in combining the twin problems of material waste and food waste, the solution is a sustainable wood substitute made from the waste potato peelings created from industrial food processing.

The invention saw Minkley recently announced as the UK's "most promising young engineering entrepreneur" by the Royal Academy of Engineering Enterprise Hub.

The manufacturing process mimics that of MDF, except that the formaldehyde-based resins are replaced with waste-derived biodegradable binders. The raw potato peel is put through refinement processes to create a binding agent that can be applied to the fibres, which include potato skins, bamboo, recycled wood or even hops before being heat pressed into a sheet of board.

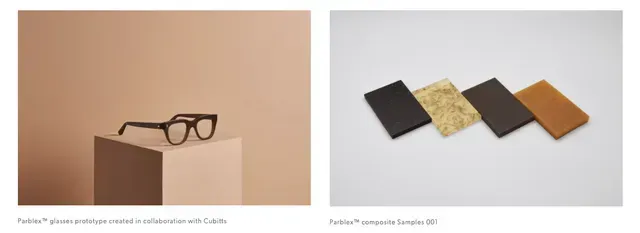

And it doesn't end there.... Chip(s) Board has moved forward by developing bio-plastics and bio-plastic composites that perform the same as conventional plastics whilst being biodegradable and recyclable post use, known as Parblex.

image credit and to see more - www.chipsboard.com